Gallery

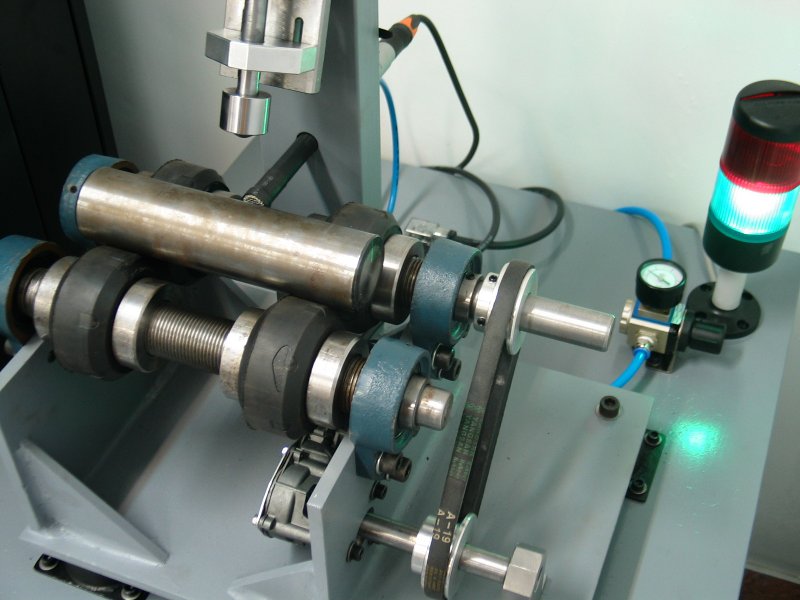

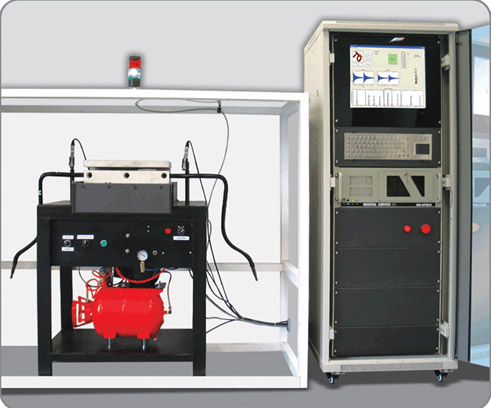

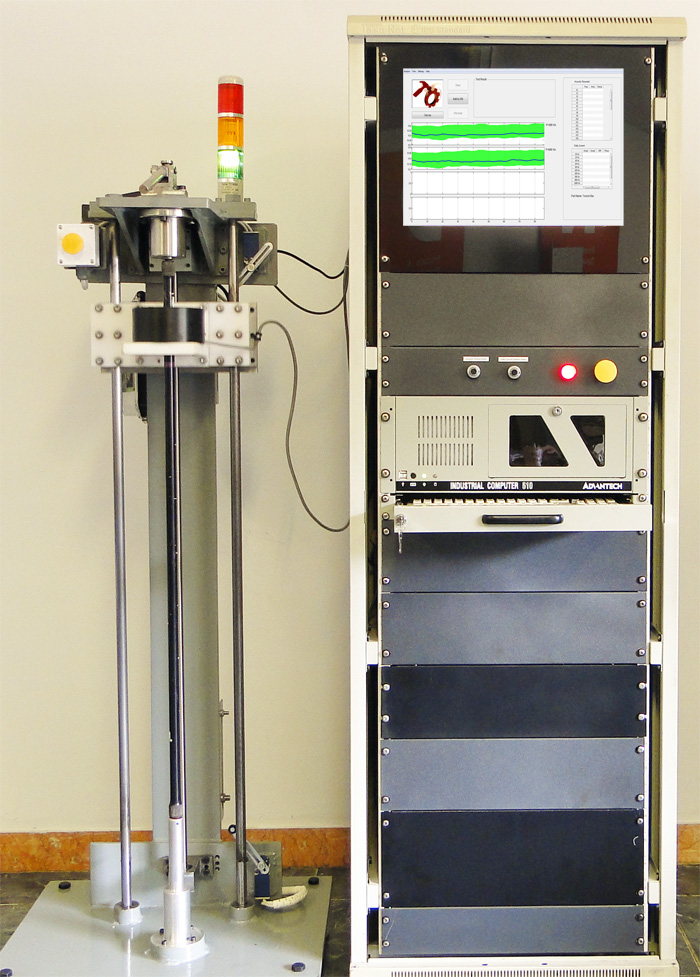

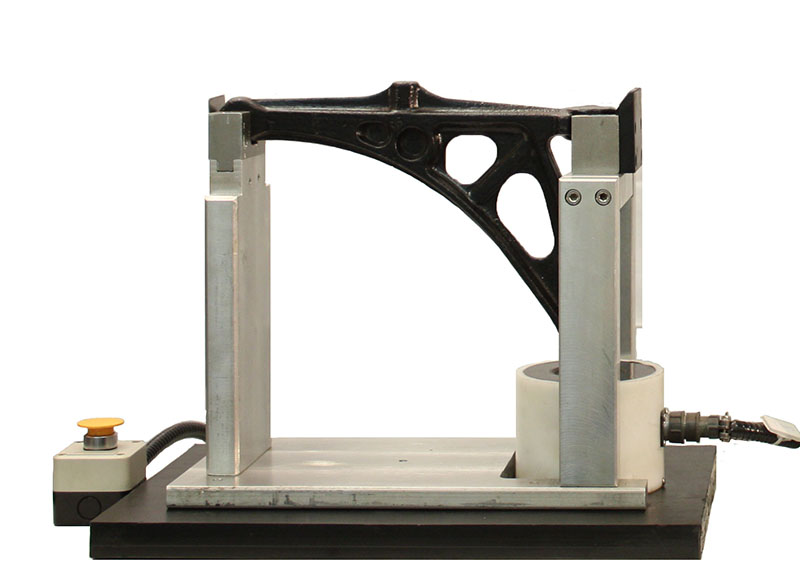

Axle Shaft Test Equipment

Axle Shaft Crack Detection Fixture

Typical safety parts controlled for structural defects

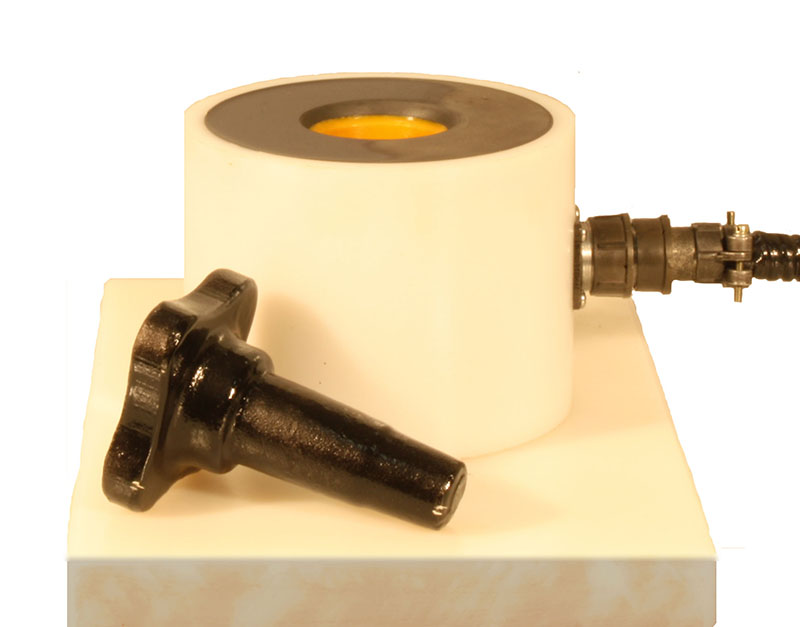

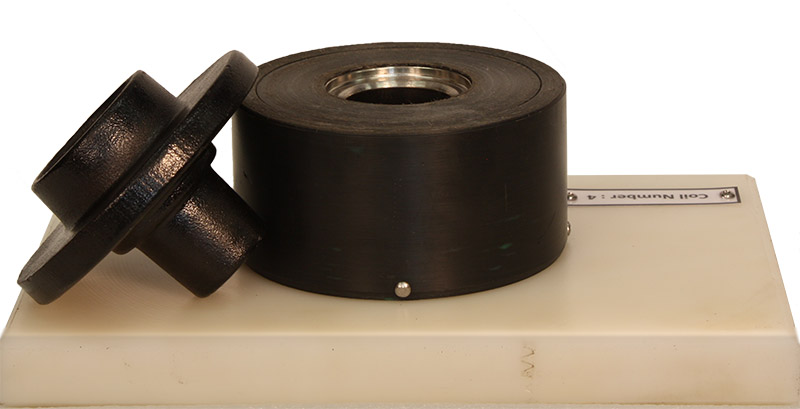

Eddy Current Equipment

Eddy Current Accessories

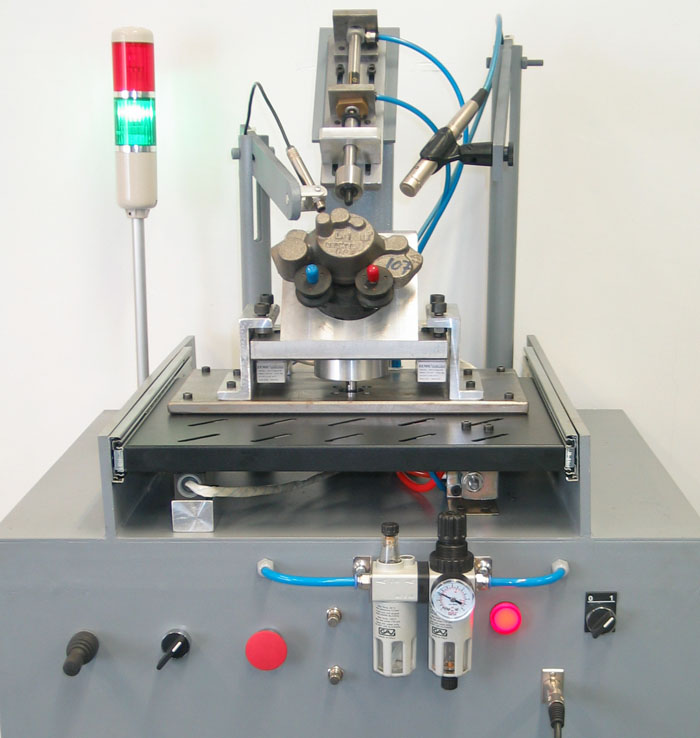

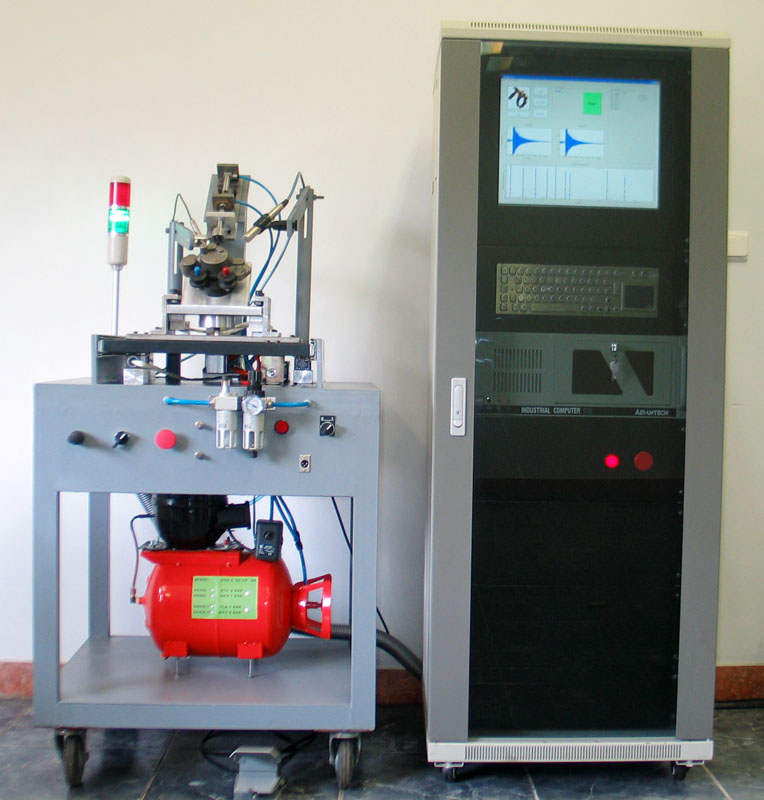

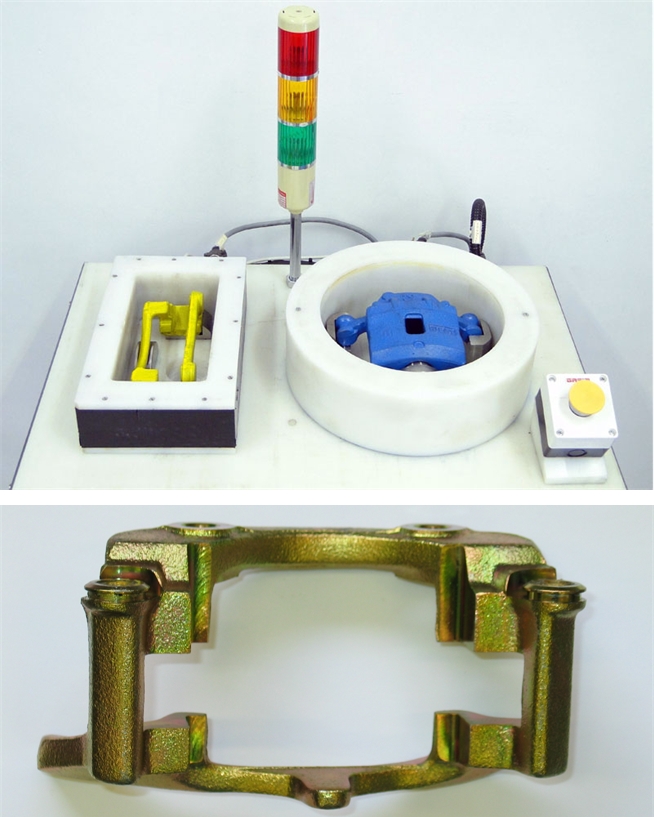

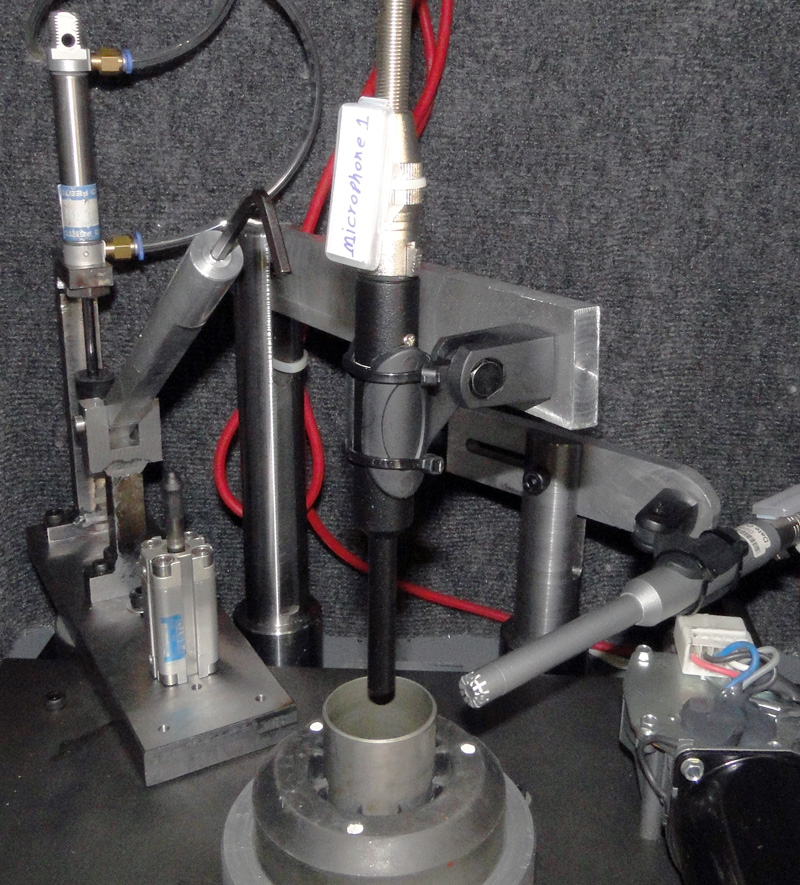

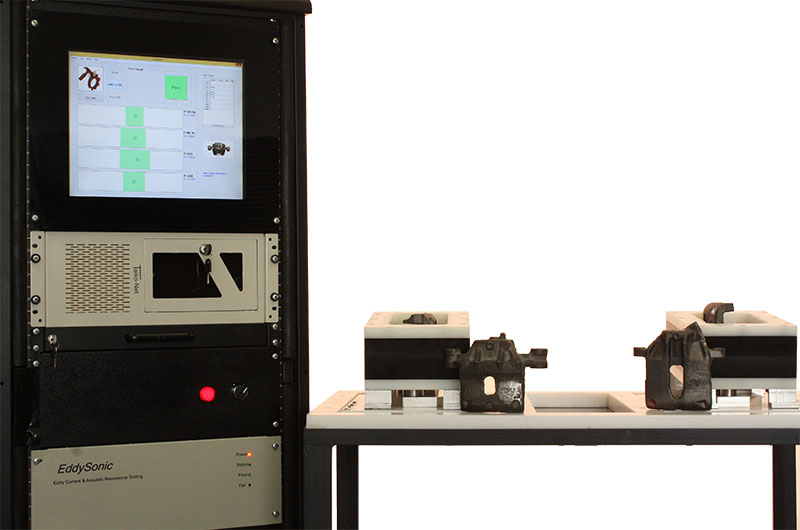

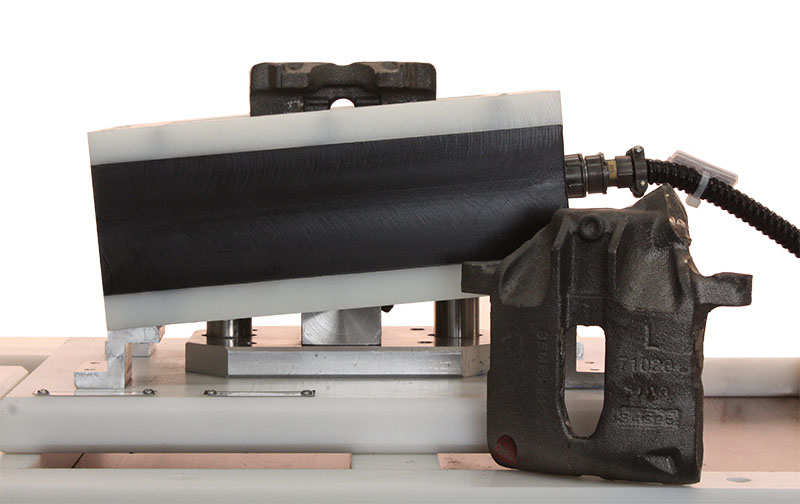

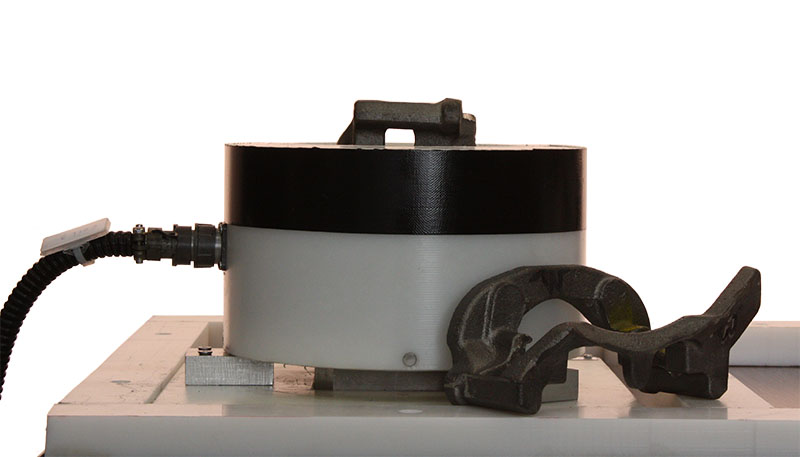

EddySonic-AR, Acoustic Resonant Inspection of Brake Caliper

Detection of defects in Nodularity, Crack, Cold Shot, and Dimension

Brake Caliper Nodularity Test Equipment

Eddy Current Testing of Knuckle Arm

Eddy Current Testing of Knuckle Arms

Eddy Current Testing of Control Arm

Stabilizer Bar Hardness Control

Air-and-Exhaust-Seat-Crack-Detection

Ultrasonic Sonotrode Analysis

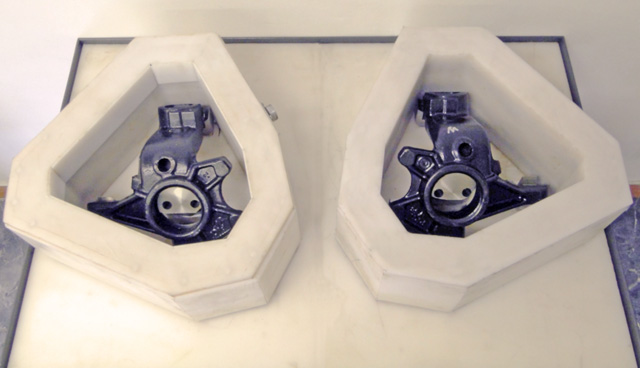

Knuckle Arm Nodularity Inspection

EddySonic-AR, Acoustic Resonant Inspection of Driveline

Crack detection of drivelines. Detection of Longitudinal Cracks based on Frequency Split.

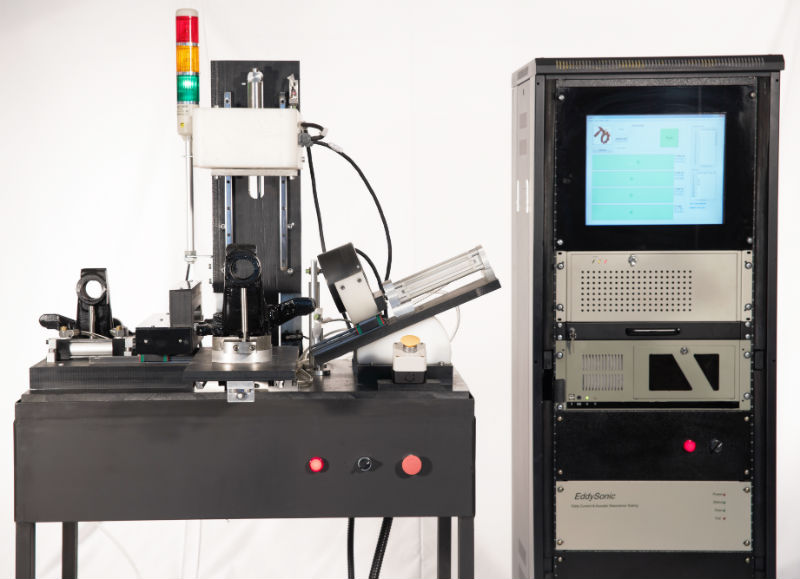

EddySonic-EC, Eddy Current Testing of Brake Caliper parts

Detection of defects in Hardness and Structure

EddySonic-EC, Eddy Current Testing of Trailing Arms

Detection of defects in Hardness and Structure

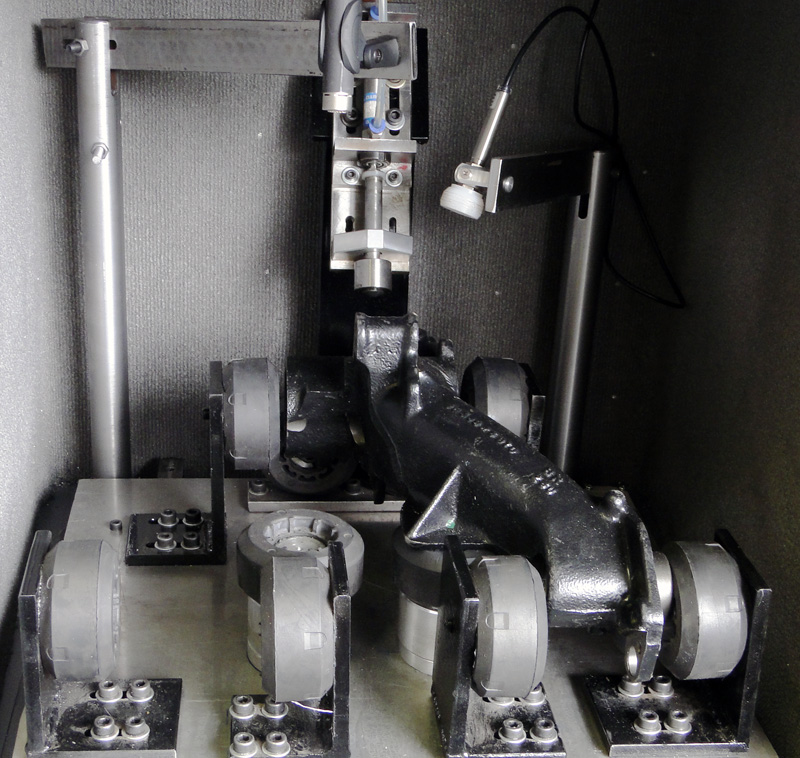

Knuckel Arm Acoustic Resonance Inspection

Control Arm Eddy Current Inspection

EddySonic-EC, Eddy Current Testing of Conrod (Connecting Rod)

Hardness testing of conrods

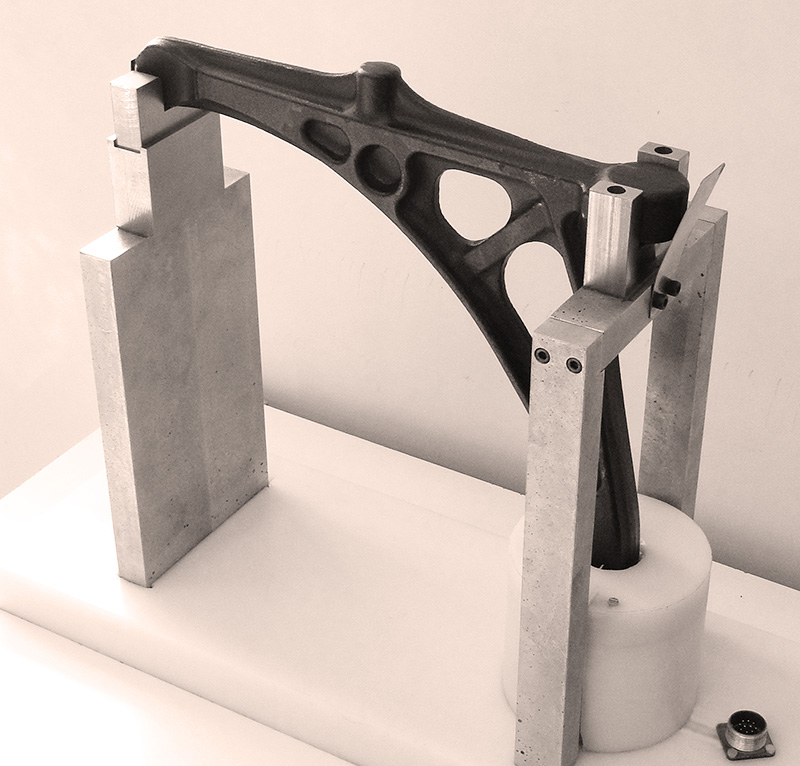

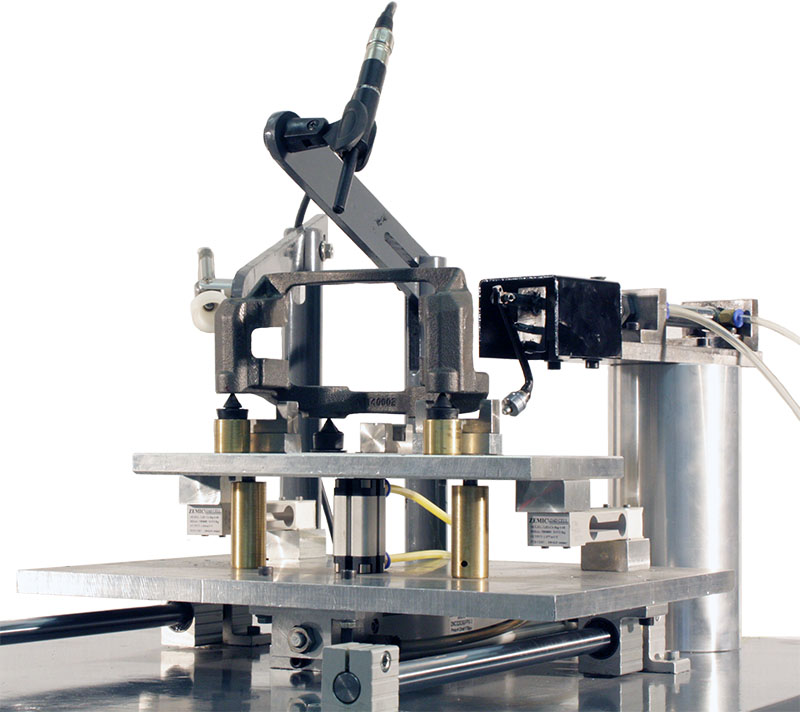

EddySonic-AR, Acoustic Resonant Inspection of Knucle Arm

Detection of defects in Nodularity, Crack, Cold Shot, and Dimension

WideBand Vibration Platform

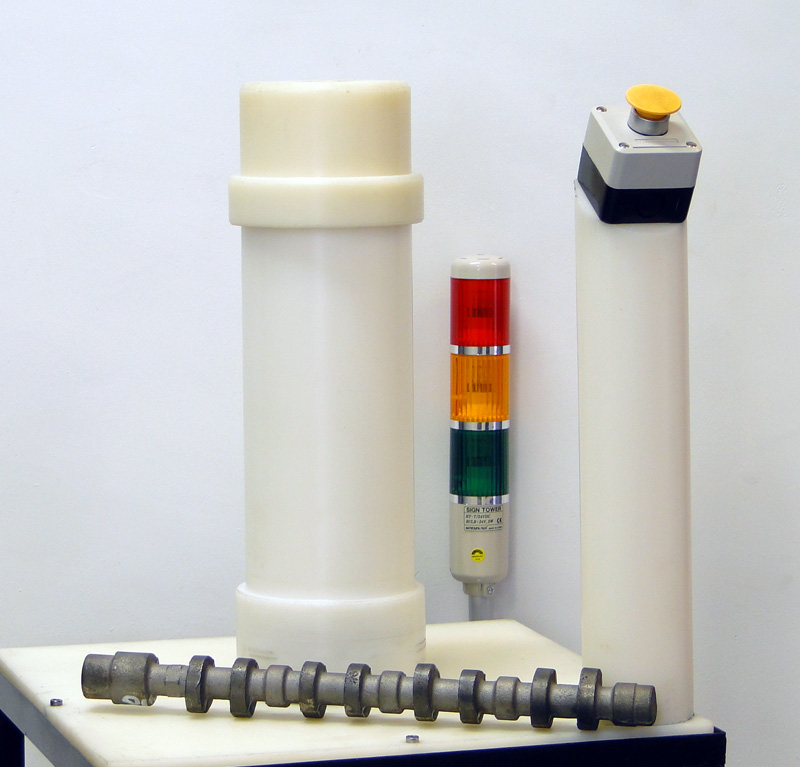

EddySonic-EC, Eddy Current Testing of Camshaft

Hardness and Carbide testing

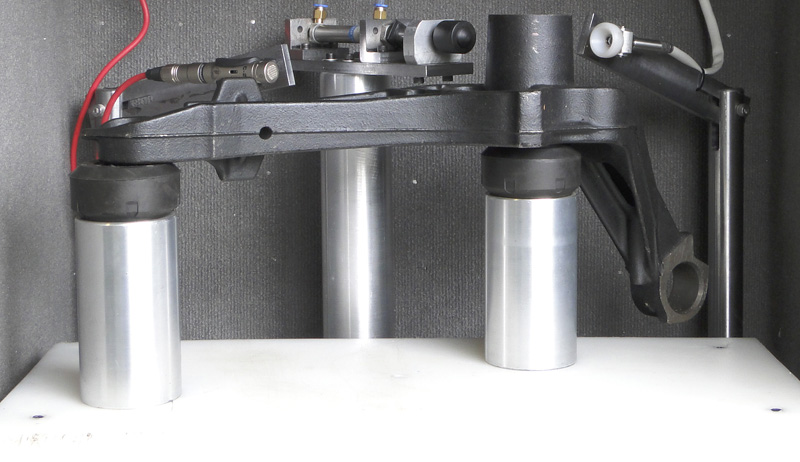

EddySonic-AR, Acoustic Resonant Inspection of Trailing Arm

Detection of defects in Nodularity, Crack, Cold Shot, and Dimension

EddySonic-AR, Acoustic Resonant Inspection of Control Arm

Detection of defects in Nodularity, Crack, Cold Shot, and Dimension

EddySonic-AR, Acoustic Resonant Inspection of Tappet Valves

Crack detection using two HF microphones based on frequency split and mode damping

EddySonic-EC, Eddy Current Testing of Trailing Arm, Knuckle Arm, and Control Arm

Detection of defects in Hardness and Structure

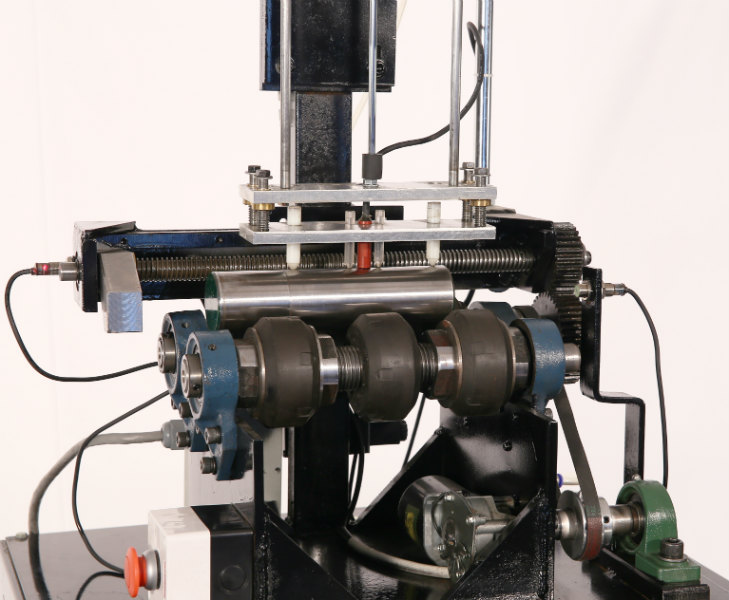

Eddy Current - Realtime Scanner - Torsionbar Heat Treatment Test

EddySonic-EC, Eddy Current Testing of Axle Shafts

Hardness and Case Depth Testing of Shafts. 3-channel coils for local testing.

EddySonic-EC, MultiChannel Eddy Current Testing of Knuckle Arm

4-Coil Eddy Current Testing of Knuckle Arm for detection of local defects in Hardness, Structure, and Carbide

Eddy Current Crack Detection of Shaft

Crack detection using HF differential probe installed in rotating and scanning fixture.

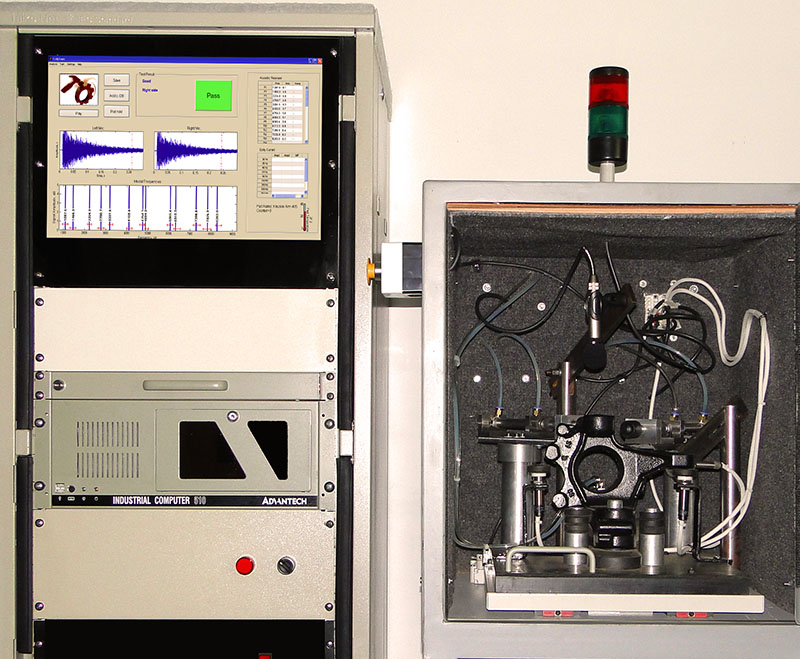

EddySonic Controller Unit

Controller Unit of Acoustic Resonant and Eddy Current Testing

Modal Analysis of Knuckle Arm by FEM

Modal Analysis of Control Arm by FEM

Modal Analysis of Trailing Arm by FEM

Modal Analysis of Brake Caliper Housing by FEM

Modal Analysis of Brake Caliper Bracket by FEM

EddySonic-EC, Eddy Current Testing of Control Arm

Hardness testing of Control Arm

EddySonic-EC, Eddy Current Testing of Control Arm

Hardness testing of Control Arm

EddySonic-EC, Eddy Current Testing of Knuckle Arm

Hardness testing of Knuckle Arm

EddySonic-EC, Eddy Current Testing of Wheel Hub

Hardness testing of Wheel Hub

EddySonic-EC, Eddy Current Testing of Wheel Hub

Hardness testing of Wheel Hub

EddySonic-EC, Eddy Current Testing of Brake Caliper Housing

Hardness Testing of Brake Caliper Housing

EddySonic-EC, Eddy Current Testing of Brake Caliper Housing

Hardness Testing of Brake Caliper Housing

EddySonic-EC, Eddy Current Testing of Brake Caliper Bracket

Hardness Testing of Brake Caliper Bracket

EddySonic-AR, Acoustic Resonant Testing of Brake Caliper Bracket

Nodularity Test and Crack Detection

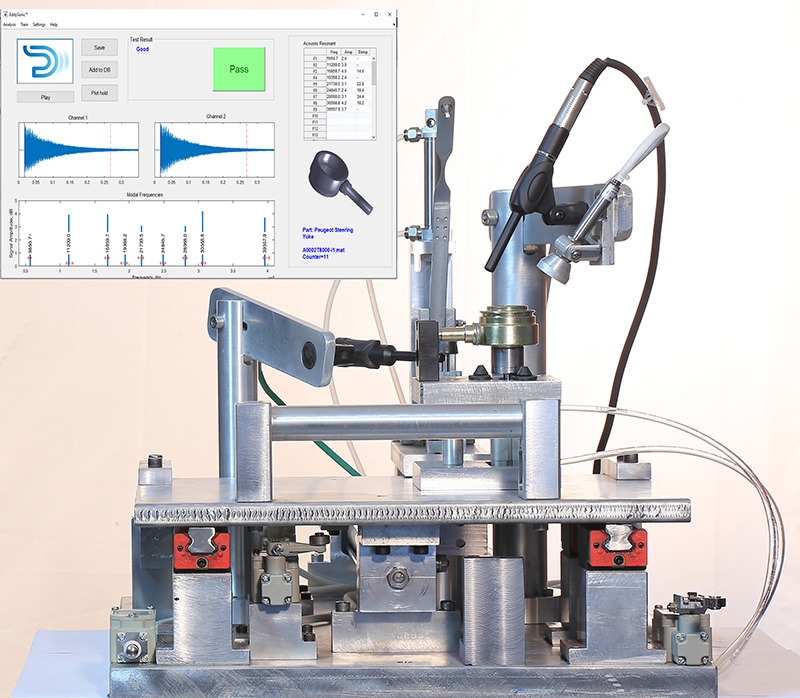

EddySonic-AR, Steering Yoke Crack Detection

Crack detection of Steering Yokes after friction welding

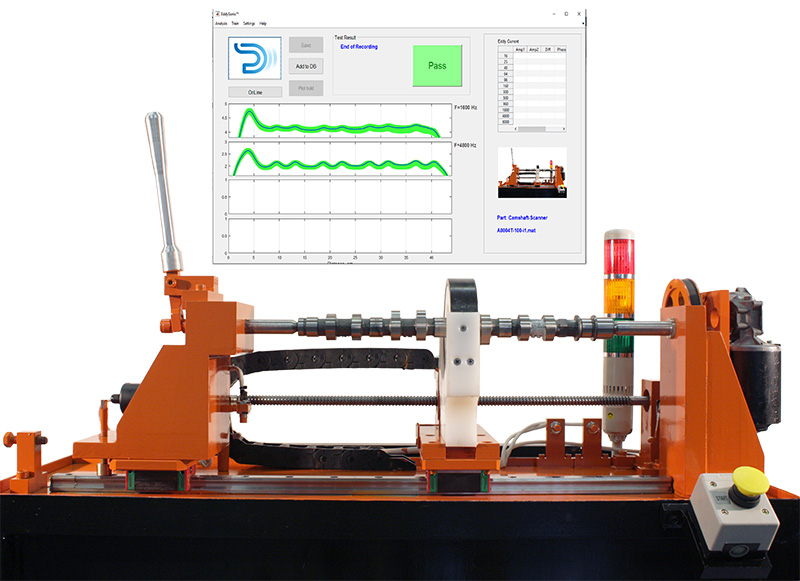

EddySonic-EC Eddy Current Scanning of Camshaft

EddySonic-EC Eddy Current Scanning of Camshaft to test local defects (Hardness, Carbide, Structure). Highly Spatial Resolution, Accurate and High Speed, Multi-Frequency Testing